Insight | Nov 06, 2019 | Arora

Improve Productivity with a Real World Scheduling Solution

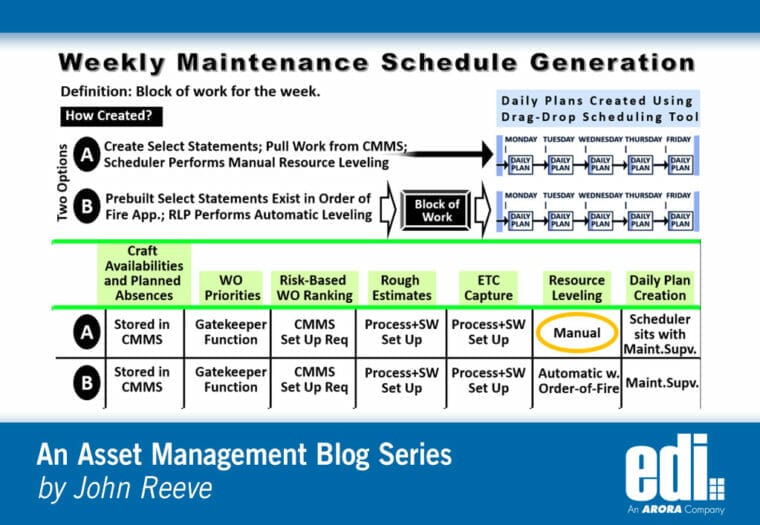

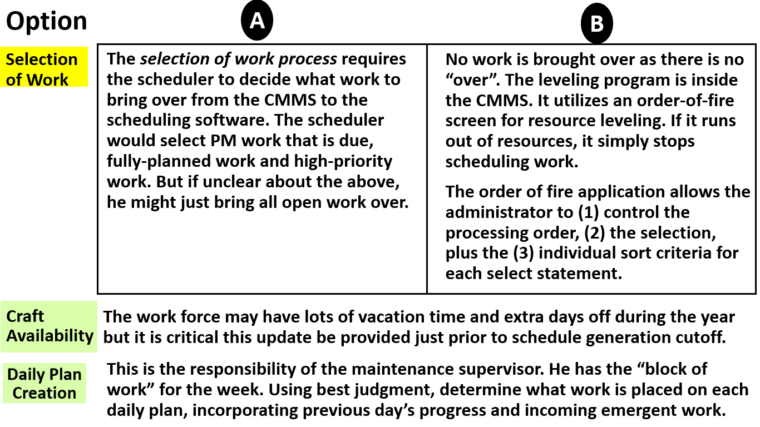

Resource leveling is a key step in the maintenance process. Organizations decide to either perform a manual process (20 man-hours per week) or an automatic process (2 minutes).

- Option A takes work from the CMMS and, with help from the maintenance supervisor, the scheduler operates the drag-drop software to manually place work into each of the daily plans. This drag-drop tool balances work against resources on screen. Depending on the software product, there could be an option to automatically populate the daily plans, but it is seldom used due to a variety of reasons (discussed below).

- Option B creates a “block of work,” perfectly balanced. The scheduler is done. The maintenance supervisor however must create the individual daily plans, using the set of work. The drag-drop tool could still be used after selecting the approved “block of work.”

Subjective Selection

If the creation of the Daily Plan is basically a “sit down” between the scheduler and the maintenance supervisor, this is called “subjective selection” – and a bad practice. This approach will likely not select work that was given high marks by risk-based prioritization algorithms, nor will it maximize craft utilization.

Why Does a Maintenance Scheduler Need to Be Present to Create Daily Plan?

Answer: Not really sure. Perhaps he is the only one who can figure out how to make the drag-drop tool work. So, question number 2 is, “Why do we need a drag-drop tool to create a Daily Plan? We already performed resource-leveling for the week.”

Although Option A looks to be more glamorous, this is unnecessary time spent by the maintenance scheduler, sitting with each craft supervisor to pick and choose what work they want from the backlog. Not only are they figuring what work orders to choose, but also what day of the week and worker name.

We Just Don’t Trust Our Backlog

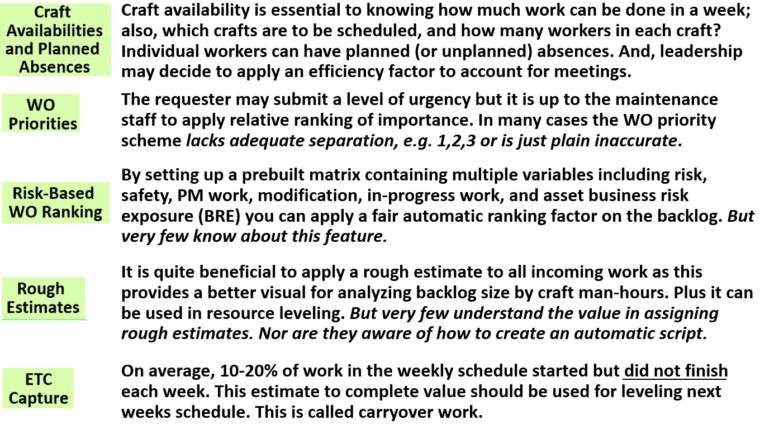

The real roadblocks are:

- Inaccurate backlog

- Minimal craft estimates

- Poor work prioritization

- Stale work

- Work marked as open, but it’s really done

And, because there are management KPIs in place, the supervisor may be under-scheduling the work force. There are also scheduling software limitations, such as:

- The leveling software cannot apply a separate sort value to each selection statement

- The software does not cleanly capture ETC values or accommodate standing work orders

All of the above discourages administrators from automating the weekly schedule process.

Does It Have to Be This Complicated?

Food for Thought

The percentage of organizations who even try to make a weekly maintenance schedule is less than 20%. Hence this final thought: There are probably more people who have bought the Maintenance Planning and Scheduling book than who have successfully implemented maintenance weekly scheduling. Isn’t it time to provide a common-sense solution that could have a dramatic impact on all industries around the world?