Cheyney University WWTP Upgrade

Cheyney University of Pennsylvania has had an on-site wastewater treatment plant (WWTP) since 1912. Over the years this plant has added, removed and upgraded equipment to accommodate the increasing volume of waste dispensed by a growing student population.

With the advent of new dormitories and associated campus building upgrades to support the growing student population, the demolition and replacement of the existing wastewater treatment plant was imperative.

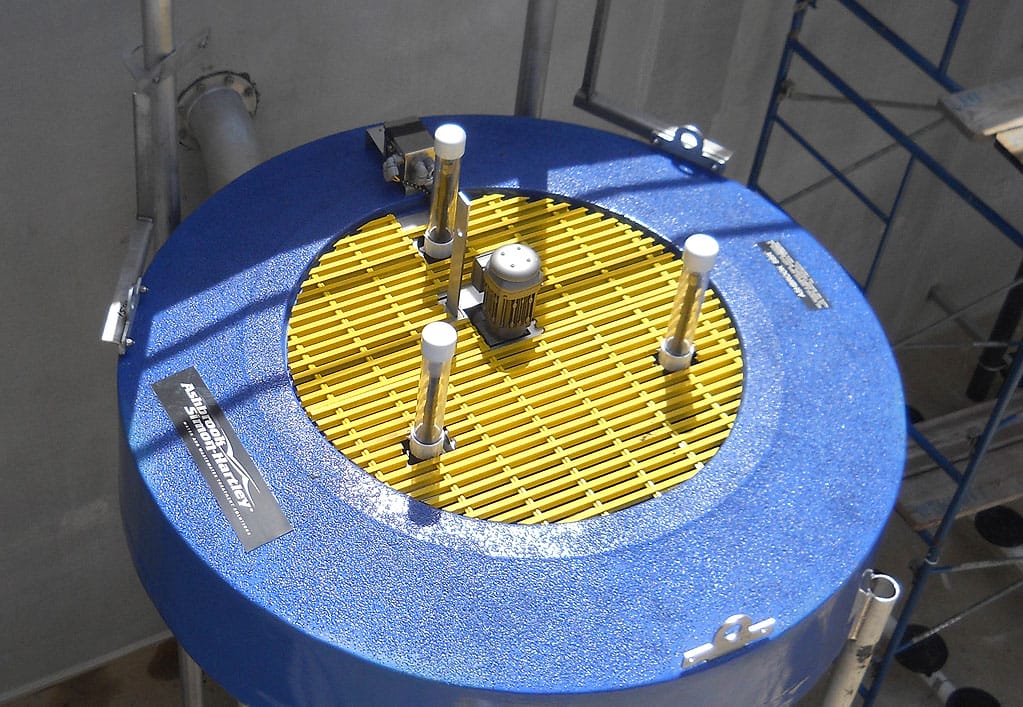

The new wastewater treatment plant consists of a new outdoor raw process screening area, a new process building with an outdoor secondary treatment process and a new tank building. Arora provided MEP and lighting design for the new WWTP.

The project was split into two phases to ensure uninterrupted processing capability.

SCOPE OF SERVICES INCLUDED:

Electrical engineering tasks:

- Connecting into the existing 5 kv campus-wide electrical-distribution system via a new 5 kv switch with associated automatic transfer switch at the location of the new process building. The campus electrical-distribution system is a redundant dual-feed distribution system to each building on campus.

- Power distribution to all process motors and pumps via a new motor control center.

- Local branch circuit panelboards to support exhaust and ventilation fans as well as plumbing equipment requiring power.

- Lighting design at the outdoor raw screening process area, new process building, tank building, and outdoor secondary treatment process area.

- Power ductbank from the existing manhole system to a new outdoor switch and transformer location at the new process building as well as equipment located remotely from the new process building.

- New grounding-loop system for the new process equipment and buildings, new lightning protection system atop the new process and tank buildings, indoor and outdoor general-purpose receptacles at all buildings, and electrical load calculations for the new equipment loads connecting into the existing distribution system.

Mechanical and plumbing scope:

- Exhaust and ventilation systems for the process and tank buildings.

- Electrical unit heaters for heating the spaces in the new process and tank buildings.

- Providing a hot-water heating system for hot and cold running water in the lab area and toilet room as well as sanitary requirements.

- Supplemental piping system for the process-building equipment.

- Gas calculations for increasing the gas service to this project.