Insight | Sep 18, 2019 | Arora

It’s Hard to Know, What You Don’t Know

When is a Roadmap a Roadmap?

Is your “roadmap” simply a software release schedule showing upcoming new features from the vendor? Or is it a comprehensive plan for asset management and operational excellence?

Scheduling Solutions

Is drag-and-drop functionality the only feature you are after? And is subjective selection your primary method for determining what work goes on the weekly schedule? Or, would an automated, resource-leveled weekly schedule, utilizing a risk-based prioritization, add more value? Then, once the “set of work” is selected for the week, the drag-and-drop tool can be used to create the Daily Plan.

Would it be helpful to have ONE scheduling product that handles CMMS daily/weekly, plus large project scheduling that requires logic ties, total float calculations, and ETC capture? This “product” doesn’t exist by the way (as of September 2019). So, why haven’t the scheduling vendors pursued this? Answer: (reason 1 of 2) The CMMS user community is not asking.

Bar charts might look pretty, but should this be your only requirement? I would focus more on the automation of resource leveling. The scheduler should be doing more than spending the entire day building schedules relying on subjective selection. Note: If your backlog of work is generally NOT accurate (as to statuses and lack of work estimates) it will be hard to automate anything. Perhaps this is (reason 2 of 2) why organizations fail to advance in this area.

Major Project Scheduling

From a project management standpoint, you should start all projects with a WBS tree to manage scope and deliverables. The WBS cost account level should be linked to the CMMS work order to capture actual costs. Once the WBS is in place, use PERT charts to establish activity relationships. Speaking of PERT charts, they would be helpful to the planners who occasionally need to convey a complex set of events to the customer [PERT chart for planners, but without dates]. The last step is to build out the schedule activities for each WBS cost account, provided you had a decent scheduling tool.

Who’s on First, What’s on Second

Is the purpose unclear? Is the question, “Who is running the CMMS?” or is it, “Who is responsible for the Asset Management System?” Does a cross-functional Core Team exist, or is the system run by one person? Does a business analyst regularly survey the working level to ensure buy-in, or is that assumed? The asset management core team should be responsible for the success or failure of the system.

Do You Have an Asset Management System or a People Tracking System?

Perceptions are important. The working level, as well as upper management, may not be properly informed as to real purpose. For example, are metrics implemented that focus solely on worker productivity (i.e. labor hours worked in a day) and nothing on asset reliability? Do actual hours get sent to the ERP payroll first, and then the CMMS?

Bad Actors (Assets)

Where should the focus be? Does it seem like everyone asks about your failure code design, and no one asks about the analytical reports needed to dissect the data to find worst offenders? Can leadership extract the Top 10 bad actors from the CMMS and drill down to find cause? Or is this analysis merely a tribal knowledge exercise?

System Maturity

Does the vendor representative ask you, “How many of our industry solutions (or software applications) are you using?” to see how well you are doing. Or, do they ask you “How well can you extract value from your asset management system?” Does the maintenance staff just enter actual man-hours, or do they also provide valuable feedback on PM records, defects, failure modes, maintainability, safety, and design flaws? Are all assets identified in the CMMS, or is there a large percentage still outside the system? Do you change out assets (during repairs) but keep the same asset primary key?

Is There Confusion Between Failure Codes and Failure Modes?

Have you spent the last 3 years trying to build-out a failure code hierarchy, and still going? Or, did you design the failure analytic first, and then work backwards to identify the exact inputs you needed? Lastly, does leadership understand the importance of chronic failure analysis? SAE JA1011 is the RCM standard which defines failure mode. You might try to find these 2 words in the CMMS on-line help.

Does an Asset Manager Role Exist?

Was your last implementation/upgrade mostly an IT project? Or, were business processes also evaluated? Do you only attend software-centric user forums, or do you also attend reliability venues?

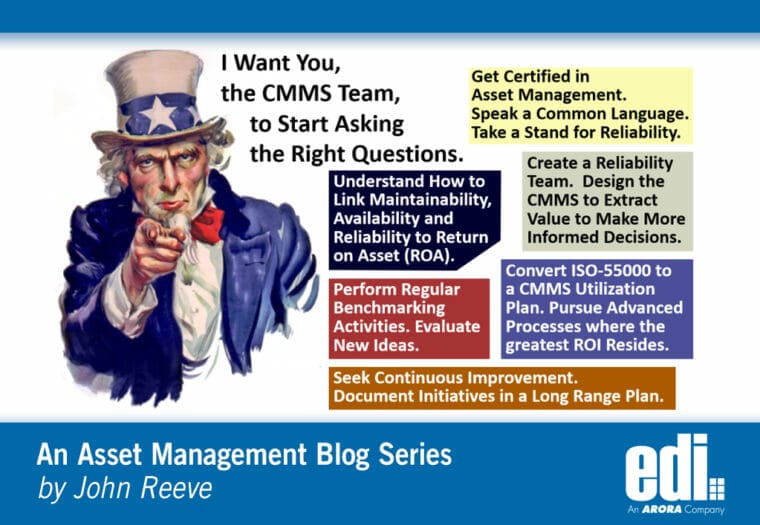

Who Should Get Certified?

Certifications in the world of reliability add value. I would find project leaders who are implementing a CMMS and suggest that they also have this background. Ideally, there are internal staff members that are doing the implementing. And anyone who has interest in asset management, or the title of Facility Director or Reliability Engineer, would find value in a certification. Without trying to push a particular certification, the goal is to understand all the essential key elements that make up an asset management system, which includes definitions. For me, starting out as a CMMS consultant, this additional knowledge enabled me to visualize unique solutions inside the base product, that no one had ever thought of before, which was key.

Books from Reliability Web

I dive deeper into this subject with my recent book, Demanding Excellence from Your Asset Management System. Also, as a related subject, Failure Modes to Failure Codes.